Serrations. We didn’t want them because we weren’t given the choice.

Serrations on EDC folders and fixed blades became very popular in the 1990s following Spyderco’s lead.

Serrations are a way to extend the cutting life of a blade, pushing back the need for sharpening by a substantial margin.

That’s why the cheapest kitchen knives are serrated, the makers of those know their owners wouldn’t sharpen them, even if they could take an edge! No, they use them until they’re dull, then throw them in the junk drawer.

On an EDC knife, the idea is the same - extend the cutting life of the edge in case you cannot or will not sharpen it.

But serrations are so much more.

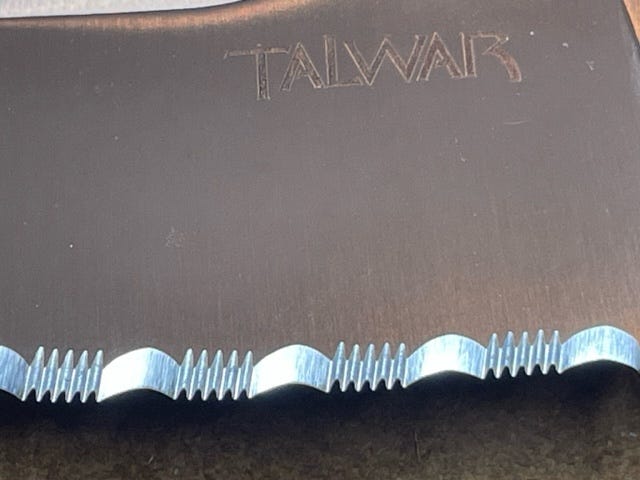

Looking closely at serration patterns. One thing they have in common are scoops and peaks, or, as I like to call them, hawkbills and daggers.

Large, scooped-out, sharpened curves (like hawkbill blades) are punctuated by 3 to 5 pointy peaks (like daggers). Pulling this edge profile across a tough or slick medium will show you there’s nothing a hawkbill and some daggers can’t cut.

Need to start a cut in a fibrous piece of rope? Serrations will do that much better than a razor-sharp, polished edge.

Need to cut through a leather jacket or military rigging? Serrations dig in, and even when relatively dull, they will not skate off the target.

Hard using a blade with “inferior” blade steel? Make it partially serrated to keep the work going even after the main edge has gone dull.

I go down the serrations rabbit hole on this week’s Mid-Week Supplemental podcast (episode 437) - dropping on Wednesday, Aug. 9 - and show the different patterns used by makers like Spyderco, Emerson, Microtech, Cold Steel, and others. Be sure to subscribe to the YouTube channel or subscribe to your favorite podcast app if you’re not already so you don’t miss it!

Serrations. When you really don’t want to take dull for an answer!

Knife Junkie Out!

Bob

Get early access to the podcasts, extra “bonus” content from our podcast guests, the pride of being a Knife Junkie supporter - and at the Gentleman Junkie level, be entered into our monthly knife giveaway! Become a Patron today!

American Blade Works: The Knife Junkie Podcast (Episode 436)

Michael Martin of American Blade Works (ABW) joins me on Episode 436 of The Knife Junkie Podcast.

Michael started American Blade Works at his home in North Carolina and is devoted to constant quality improvement in design and build. A quintessential small business, American Blade Works is a one-man shop, though his wife plays an important role in the business.

American Blade Works makes some of the most refined and respected CNC-made small-batch knives in the U.S.

Find Michael and American Blade Works online at www.americanbladeworks.com and on Instagram at www.instagram.com/americanbladeworks.